Premold Corp: RIM Press Re-Engineering

RIM press gets an elegant engineering makeover to simplify operations and improve reliability.

- Industrial / Commercial Products

ReIMagining the over-engineered

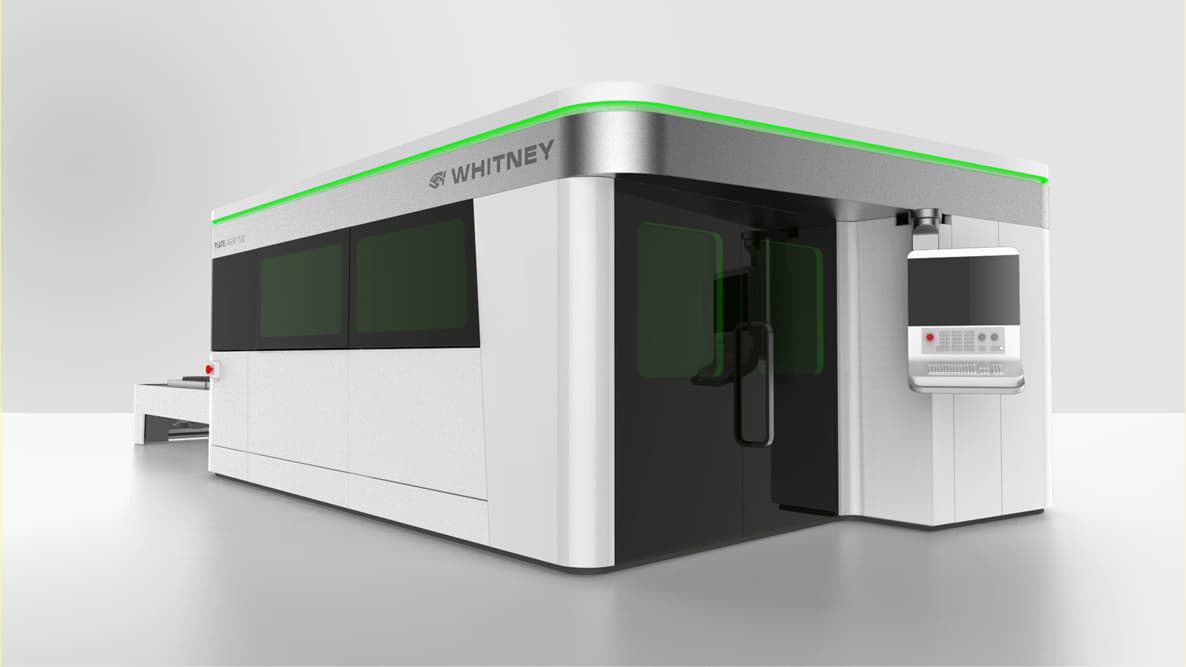

When it comes to manufacturing plastic parts, Reaction Injection Molding (RIM) offers companies the opportunity to produce smaller quantities with a more modest upfront investment.

Delve first got to know Premold Corp, leaders in RIM manufacturing for more than 25 years, as a trusted vendor for our clients. Eventually, Premold also became a client of Delve.

When Premold was looking for a RIM press with specific capabilities that were unavailable on the market, Delve helped engineer a design solution that reduced set-up time, labor and overall cost for Premold’s customers.

Ken Schweitz, president and owner of Premold, and his team were so happy with the innovative design that they had a second version built.

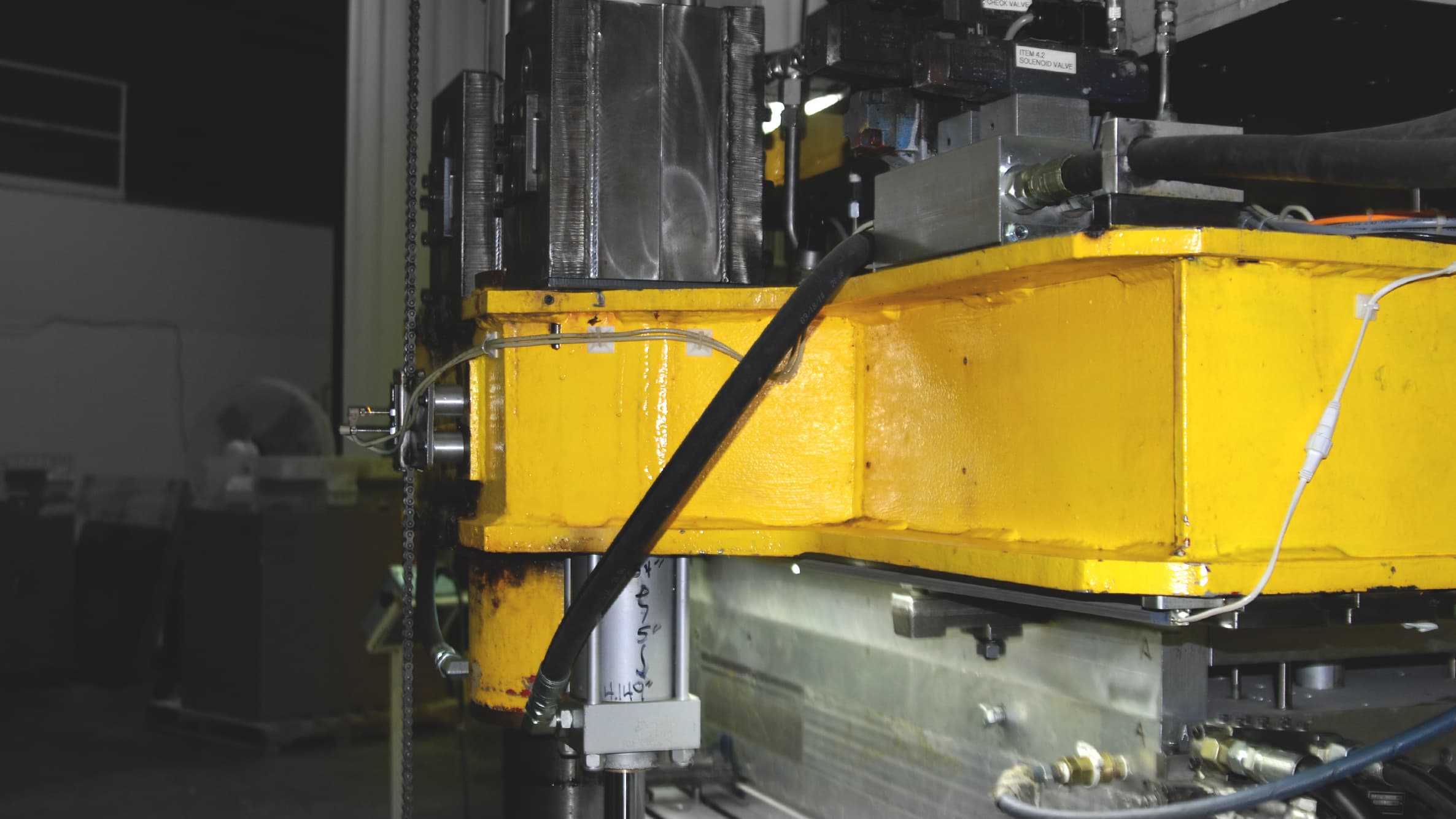

Fast-forward a few years. Premold was doubling its facility size, strengthening its in-house prototyping capabilities and adding equipment to accommodate its customers’ growing needs. An off-the-shelf German RIM press wasn’t functioning as effectively as hoped. The press was over-engineered and difficult to operate and maintain.

Shutting down the press to address these issues was decreasing productivity, frustrating operators and creating more work for maintenance technicians.

Remembering their positive experience with Delve, Premold’s team gave us a call for some additional engineering brainpower.

“We knew all the people at Delve who would be involved so we were comfortable with what they could bring to the table,” Schweitz said. “It was a smaller project that went very quickly and efficiently.”

The Delve and Premold engineering teams collaborated to eliminate unnecessary complexity. In particular, engineers simplified the press’ wiring and removed a superfluous hydraulic braking system.

The project proved to be an exercise in restraint as brake pads were also purged and the number of hydraulic valves were greatly reduced.

When it comes to maintenance, fewer parts is a very good thing.

The rebuild took about two months, but saved countless production disruptions.

Operators enjoy using the simpler, more straightforward press and Schweitz enjoyed his sophomore run with Delve.

When asked to characterize what it’s like to work with us, he said, “High competence, easy communications, honesty and sincerity.”

Learn more about our Product Design & Development: Industrial & Commercial expertise.